Description

What is a DC Brushed Tachogenerator?

A tachogenerator gauges the speed of rotation of a shaft or disk (from Greek: tachos = speed, metron = measure) as in a motor or other machine. The device usually displays the rate of revolutions per minute (rpm) on a calibrated analogue dial.

Radio Energie REO444 Type 60V/1000rpm Flange mounted brushed Tachogenerator with a terminal box

Radio Energie REO444 Type 60V/1000rpm Flange mounted brushed Tachogenerator with a terminal box

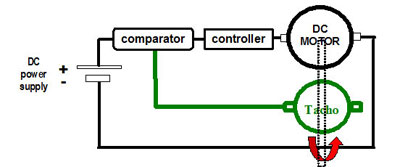

The DC motor speed is continually adjusted by the controller according to the speed measured by the tachogenerator. The tachogenerator transforms the motor speed into voltage so that the comparator may check and adjust if there’s a difference between the setting speed and the effective speed.

Generalities

Over recent years, the control process of electric rotating machines has undergone a number of changes linked to the development of new technologies and new material. In the majority of cases, these machines need a speed measuring device a tachogenerator or encoder which gives an accurate measurement of the speed (RPM) in the closed loop process.

The use of digital drives or PLC’s in automated systems suggests the use a digital speed sensor (encoder) to control the speed of the motor. However, the electronics usually permits the drives with inputs of 0-10V to use an analog speed sensor (tachogenerator). Therefore, the use of tachogenerators is possible for a lot of applications. The advantages are in excellent performances and a low time constant.

Principles and Applications

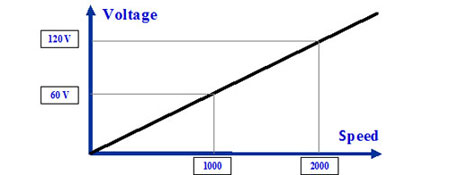

A tachogenerator is an electric generator that provides a voltage proportional to the speed. As tachogenerators are key components in automated systems. They must be strong, reliable, accurate, sensitive and stable. These analogical sensors (DC tachogenerators, AC tachogenerators, brushless DC tachogenerators) are adapted to every industry like machine tools, proportioning systems, handling and lifting systems, lifts, paper manufacturing machinery, textile machines, glass production lines, rolling mills, railway industry, etc.

These sensors are manufactured in different mechanical variations and frame sizes, and also in various electrical characteristics i.e. voltages between 2 volts and 6000 volts at 1000 rpm, rotating speed up to 12000 rpm, machines with shaft and bearings, machines with hollow shaft. Tachogenerators are available from different manufactures but in 1949 Radio-Energie started to make tachogenerators and the REO444 type followed shortly and established itself as the industry standard and has been copied many times.

AC Tachogenerators

These tachogenerators all have a wound stator. The voltage and the frequency are both proportional to the speed. These models can also be used as power generators, but their quality intends them for applications of controlling a drive. The absence of contact (rings and brushes) gives these generators a good stability and a good linearity of the output voltage, but the variations of concentricity and symmetry and the irregularities of the magnetic circuit can introduce a certain rate of distortion.

Some alternators can be fitted with a rectifier with which it is possible to provide a DC current proportional to the speed; in this case the polarity is constant and independent of the direction of rotation, so the drive is unable to establish direction of rotation. The linearity is affected by the rectifier and the best results are obtained for a speed higher than a certain limit which depends on the rectifier used, the provided power and the output current.

These types of tachogenerators are either homopolar with stator magnets and rotor with poles of modulation making it possible to obtain very high frequencies for the size of the machines or with rotor magnet and poles of modulation, or heteropolar with rotor magnet.

Some machines can be wound only in single-phase current, others have the possibility of being in three-phase current or even in diphase.

Signal Use

The signal is used either in frequency or in voltage.

The frequency of the pulsations of the voltage is a function of the number of segments of the rotor. It can thus reach high values. Where necessary, the output voltage can be rectified and the use of LC filters smoothes the output signal to have a voltage of good quality.

Output U = f(n) linear and possibility of numerical counting.

Linearity error

It is similar to that of a DC brushed tachogenertor

Distortion rate

It is the level of deformation of the wave of the output signal compared to a perfect wave. It is due to the harmonics of rotation and to the irregularities of the magnetic circuit.

For a good signal it is significant to have a low distortion rate.

Advantages

Use in atmospheres which can deteriorate the copper of the collectors or of the brush holders, supports particularly wet environments and hostile High rotating speed;

No or little maintenance;

Adapted to counting (with low distortion), more robust than an incremental sinus encoder;

Disadvantages

The direction of rotation is only known after the treatment of the signal in polyphase machines.